Machine Building Industry

Machines are fascinating. Getting maximum performance from machinery requires highly specialized open die forgings to produce precise finish machined components for the desired end results. Parts can be made from a wide variety of metals, including alloys of carbon steel, stainless steel, alloy steel, aluminum, titanium, nickel, or tool steel. Within each of those materials are dozens of alloys made from chemistry compositions for a particular end use.

Parts and components within machines are subject to all kinds of wear. Thus, an alloy is selected that has specific mechanical properties. Often, these properties are modified or enhanced through post-forging processes such a heat treating to achieve the desired mechanical properties for the end use.

There is an almost unlimited variety of parts that can be fashioned from these basic open die forged shapes:

Shafts, Step Shafts • Seamless Hollow Bars • Pinions • Cylinders, Blind Hole Cylinders • Rolls • Forged Flats, Blocks • Bushings • Seamless Rolled Rings • Contour Rings • Hubs: Single, Double, Center • Pipe, Heavy Wall • Discs • Gear Blanks • Flanged Shafts, Single & Double • Blocks • Round Bars

All Metals & Forge Group takes great pride in maintaining one of the most stringent ISO9001, AS9100 quality systems in the open die forging and seamless rolled ring industry. It begins with learning the customer’s end use, required forging surface condition, mechanical properties of the specified material and alloy, forged shape, heat treatment, delivery need, and competitive price, coupled with forging soundness proven by ultrasonic testing, and care in packing goods to arrive in pristine condition at the customer’s desired location. Every step is monitored by the quality system at AMFG and continuously improved.

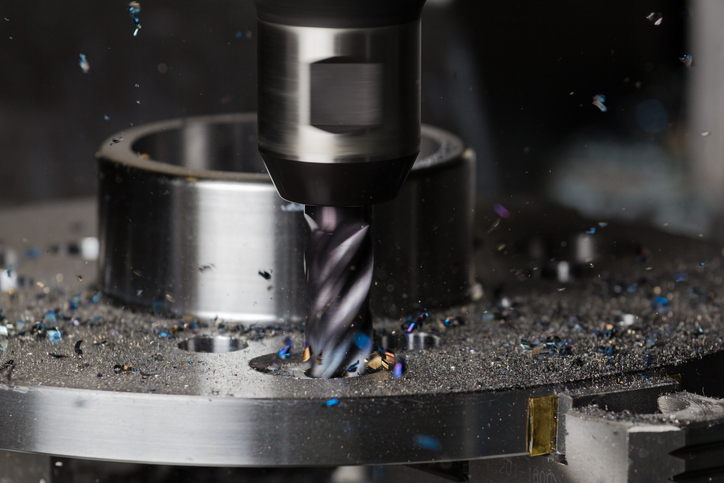

AMFG performs rough machining to within 3mm of finish dimensions to reduce the CNC cost at the customer’s machine shop for all the forged shapes the company produces. The rough machine surface condition is 250 RMS so that proper quality testing can be performed on each part – the AMFG standard.

The company can perform finish machining to within .001 of an inch for final tolerance and 64 or 32 RMS surface finish. This level of quality and precision is unique in an industry where other company’s parts are often delivered black, as forged, or with a rough machined surface of 500 RMS without the internal or external steps and dimensions to reduce machining costs.

From inquiry to invoice, All Metals & Forge Group quality is managed and not assumed. Whether the need is for one part, an entire project, or a production run, AMFG delivers.

U.S. 1 (973) 276-5000 • 1 (800) 600-9290 • Canada 1 (416) 363-2244

Fax: 1 (973) 276-5050 • Sales@Steelforge.com

Fast Quotes And Delivery

Save time and money on your next project.

In the U.S. 1 (973) 276-5000 / 1 (800) 600-9290.

In Canada 1 (416) 363-2244.

Email us at sales@steelforge.com.